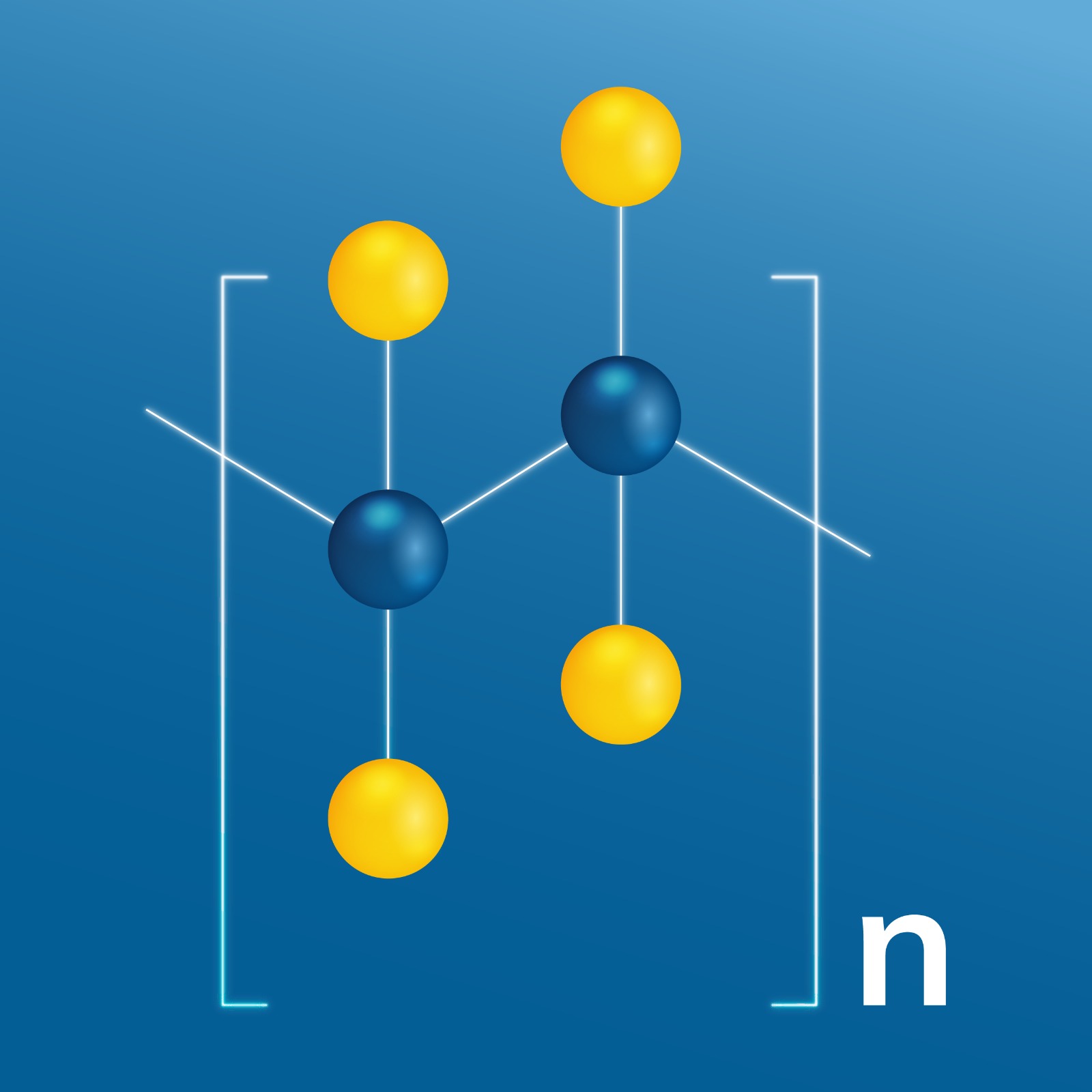

PTFE is a plastic that provides unique and exceptional properties for the industry, such as high resistance to heat, corrosion, and chemicals. It also stands out for its excellent non-stick capability (even against bacteria and microorganisms) and low friction levels.

These qualities make it an outstanding option for manufacturing replacement parts and machinery components in industries that demand high precision and durability.

PTFE can withstand extremely high temperatures up to 260°C without losing its properties.

PTFE is a non-stick material, making it ideal for coating cookware and molds.

PTFE is dimensionally stable, meaning it does not deform over time.

PTFE is resistant to most chemicals, making it the perfect choice for corrosive environments.

They enable high-volume production for commercial food processors and are commonly used in cooking and processing mass produced foods such as eggs, bacon, sausages, chicken, and hamburgers.

PTFE is used to make parts that come into direct contact with food like seals and gaskets thanks to its high resistance to corrosion and chemicals, as well as its exceptional non stick capabilities.

Used to produce parts and machinery components that require high resistance to heat and corrosion, such as in chemical manufacturing where teflon parts are used in valves and seals.

Using teflon strengthens any industry by increasing machine uptime, productivity, and durability. Additionally, its versatility allows for countless innovative applications.

PTFE is a valuable material in the energy sector, particularly in oil and gas applications, as it can coat a wide range of substrates, including carbon, steel, steel alloys, brass, and aluminum.

In deep well exploration and drilling operations, the design of engineered components must protect instrumentation from extreme temperatures, pressure, corrosion, and abrasion.

PTFE is widely used in medical equipment manufacturing due to its high non-stick capacity, corrosion and heat resistance, and its ability to be easily sterilized.

teflon offers flexibility and chemical inertness, making it reliable for medical applications exposed to chemical and biological elements.

Used to manufacture pipes, valves, and other components that must meet strict hygiene and corrosion resistance standards. Its lubricity, flexibility, batch consistency, low permeability, and heat resistance make it ideal for this industry.

PTFE is used to produce engine and brake components because of its high heat resistance and ability to reduce friction between parts.

Other applications include fuel systems (fuel lines, interconnection hoses, tank vent valves, diagnostic sensors), transmissions (internal shift seal rings, head gaskets, O2 sensor seals, A/C piston rings, valve stem seals), and many others.

PTFE or teflon can be used in countless sectors, including aerospace, smart building construction, mining, energy (in wiring or semiconductor manufacturing), as well as in oil processing, beverages, and confectionery production.

PTFE is used in the production of seals and gaskets thanks to its high resistance to corrosion and temperature.

PTFE is used to manufacture food processing, pharmaceutical, and chemical industry equipment due to its resistance to acids and alkalis.

PTFE is used in cable manufacturing because of its excellent resistance to temperature and chemicals.

PTFE is used to make machinery components that require resistance to corrosion, temperature, and wear for example, conveyor systems, mixers, and fillers.

PTFE is used as sliding plates in modern smart buildings for movement and control systems in facades and structural elements. It’s also applied in heavy machinery, mining equipment, plastic processing machines, and the medical industry for the smooth, controlled movement of surgical instruments.

PTFE is used in the production of seals and gaskets thanks to its high resistance to corrosion and temperature.

PTFE is used to manufacture food processing, pharmaceutical, and chemical industry equipment due to its resistance to acids and alkalis.

PTFE is used in cable manufacturing because of its excellent resistance to temperature and chemicals.

PTFE is used to make machinery components that require resistance to corrosion, temperature, and wear for example, conveyor systems, mixers, and fillers.

PTFE is used as sliding plates in modern smart buildings for movement and control systems in facades and structural elements. It’s also applied in heavy machinery, mining equipment, plastic processing machines, and the medical industry for the smooth, controlled movement of surgical instruments.

+52 (772) 727 9576 +52 (772) 727 9677

Prolongación Efrén Rebolledo No. 226, Col. Los Olivos, C.P. 42510, Actopan, Hidalgo.

Send us your request and we’ll get in touch with a personalized quotation.

We’ve sent you the content you requested.

Adding {{itemName}} to cart

Added {{itemName}} to cart